Polychlorinated Biphenyls (PCB) is the most important waste management issue in

the electric utility industry. This substance was commonly used in electrical

equipment prior to the late 1970s, when PCB production was banned. The effect

of this ban on Hydro and many other utilities was two-fold. The amount of PCB

in service declined as new PCB-free equipment was installed and inventories of

PCB-contaminated wastes increased as older equipment was retired.

During the 1980s and 1990s, Hydro implemented significant initiatives to reduce

risks associated with in-service equipment containing PCB. This included

removal from service or decontamination of all transformers which had been

manufactured with high concentrations of PCB. As well, all transformers filled

with large volumes of PCB-contaminated oil were decontaminated.

Some low risk older equipment such as florescent light ballasts which contain

small amounts of PCB are managed to prevent any releases into the environment,

and will remain in-service for their life. A portion of older distribution

equipment, currently in service, contains oil that is contaminated with low

level PCB. Hydro’s policy is to test this equipment for PCB contamination

during emergency and planned maintenance, and collect all PCB contaminants for

proper disposal.

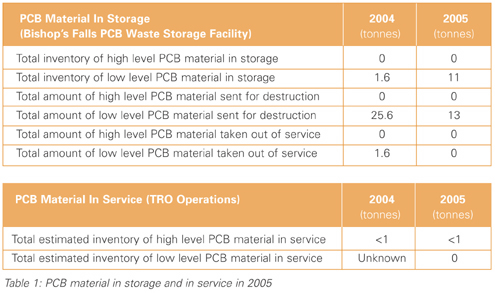

In 2005, 11 tonnes of low-level PCB material was placed in storage at our

Bishop’s Falls PCB waste storage facility. Approximately 13 tonnes of low-level

PCB material was removed from storage during 2005 and destroyed. Therefore, as

of December 31, 2005, there was no low or high- level PCB material in storage

It is recognized that some older equipment such as capacitors and fluorescent

light ballasts, which may contain high levels of PCB, remains in service. It is

estimated that there is less than one tonne of PCB contained in this equipment.

A portion of the older distribution transformers in service throughout the

system contain oil that is contaminated with PCB to a level greater than 50

ppm. Hydro has therefore initiated a program to reduce the amount of PCB

contaminated equipment in service. The multi-year program involves the

identification, testing, and removal from service or refurbishment of all

electrical equipment with a PCB level greater than 50 ppm.

Table 2 provides an inventory of PCB material in storage and in service at

Churchill Falls facilities as of December 31, 2005. At present, the total

amount of low and high-level PCB material in storage in the Churchill Falls PCB

waste storage facility is less than 1 tonne. No PCB material was sent for

destruction in 2005. PCB material known to be in service are ballasts and

capacitors; however, there is no inventory completed of this electrical

equipment to date.

Lubricating Oil

Hydro currently has a waste oil management system for handling and disposing of

various types of used oil. In the past, however, records on the amount and type

of oil being recycled were not always kept. Hydro has made significant progress

over the last couple of years in this area and now reports on an annual basis

the amount of used lubricating oil generated and new oil purchased for our

diesel generating stations to the Department of Environment and Conservation

(DOEC). In 2005, approximately 46,000 litres of used lubricating oil was

collected from our diesel stations for recycling.

In 2005, at CF(L)Co, approximately 34,000 litres of used lubricating oil was

collected and properly disposed of by a government-certified, third-party waste

oil contractor for heat recovery.

Insulating Oil

At Hydro’s central maintenance facility in Bishop’s Falls, approximately 42,000

litres of insulating oil was reused. Approximately 2,000 litres of this

insulating oil was reused following processing or cleaning by internal forces,

while 40,000 litres was reused following processing or cleaning by a

third-party contractor.

At CF(L)Co in 2005, approximately 192,000 litres of insulating oil was removed

from underground transformers and replaced with an environmentally-friendly

insulating oil.

Scrap Metal

During 2005, Hydro decommissioned 520 distribution transformers, all of which

were sold to a transformer manufacturer for reuse. In addition, scrap

aluminum/steel tower components and miscellaneous scrap were auctioned at

Hydro’s central maintenance facility in Bishop’s Falls for recycling.

During 2005, CF(L)Co, as part of the scrap metal recovery management program,

collected and recycled approximately 773 tonnes of scrap metal from areas that

were used during original construction of the Churchill Falls project.

Treated Wood

Hydro, as part of it transmission line network, manages approximately 26,000

poles of varying age. Wooden poles have an economic lifespan of about 40 years

and an in-service lifespan of 50 years. With proper management, maintenance and

refurbishment, the life can be extended by 10 years or more. In Hydro’s

transmission system, just over one third of all poles are 30 years or older and

are nearing the end of their useful life. Core samples taken from some poles in

1998 indicated that the preservation retention level was not adequate. As a

result, Hydro initiated a wood pole line management program in 2003 and it is

expected to continue as a long-term asset management and life extension

program. In 2005, Hydro treated 2,700 poles with boron rods. In 2005, 2,364

treated wood poles were removed from service; 47 were removed to landfills,

while 2,317 were recycled.

Boiler Ash

During 2005, all fuel ash produced at the Holyrood Thermal Generating Station

was disposed of in an on-site, controlled solid waste landfill. The amount of

total ash produced and disposed of at the landfill in 2005 was 420 tonnes.

Other

In 2005, CF(L)Co sent five pallets of wet cell batteries for recycling,

totaling approximately 9,100 kilograms.

|