|

The majority of waste produced at our operating facilities is disposed of through government approved

waste management systems, and do not require special handling and disposal. Below is information on

special waste handling and recycling activities.

The Hydro Group operates two approved PCB waste storage facilities located in Bishop's Falls and

Churchill Falls.

BISHOP'S FALLS

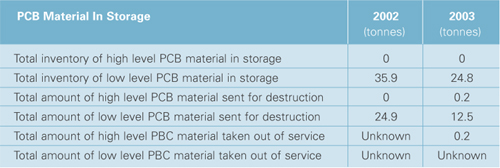

In 2003, 1.4 tonnes of low level PCB material was placed in storage at the Bishop's Falls facility. This

brought the total quantity of low level PCB material at this facility to 37.3 tonnes. Approximately 12.5

tonnes was removed from storage during 2003 and destroyed. Therefore, the total quantity of low level PCB

material in storage as of December 31, 2003 was 24.8 tonnes. As of December 31, 2003, there was no high

level PCB material in storage (Table 1), however, approximately 0.2 tonnes was sent for destruction

in 2003.

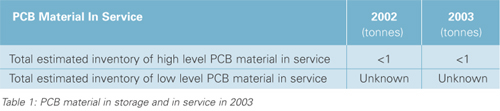

It is recognized that some older equipment such as capacitors and fluorescent light ballasts, which may

contain high levels of PCB, remains in service. It is estimated that there is less than one tonne of such

PCB material remaining in service.

It is known that a portion of the older distribution transformers in service throughout the system contain

oil which is contaminated with PCB to a level greater than 50 ppm. Hydro has initiated a multi-year

program to reduce PCB contaminated equipment in service. This program involves the identification, testing,

and removal from service or refurbishment of all electrical equipment with a PCB level greater

than 50 ppm.

CHURCHILL FALLS (CF(L)Co)

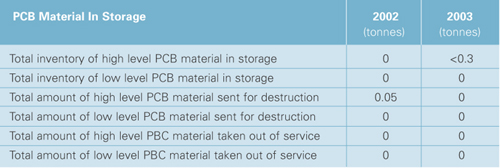

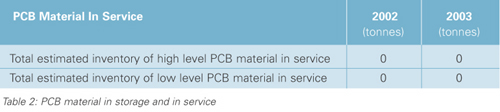

Table 2 provides an inventory of PCB material in storage and in service as of December 31, 2003, in

Churchill Falls. At present, the total amount of low level and high level PCB material in storage is

less than 0.3 tonnes. There was no PCB material sent for destruction in 2003. PCB material known to be in

service are ballasts and capacitors, however, there is no inventory completed of this electrical equipment

to date. Once draft new PCB regulations are finalized, CF(L)Co will compile the inventory of PCB material

equipment as required.

INSULATING OIL

The quantities of electrical insulating oil reused and recycled by Hydro and CF(L)Co. in 2003 was

approximately 282,000 litres.

In 2003, approximately 128,400 litres of insulating oil, which did not meet the specification for reuse,

was supplied to a third party for energy recovery.

LUBRICATING OIL

Waste lubricating oil from throughout Hydro's operating systems is captured and supplied under contracts

to government certified waste oil handlers for recycling or energy recovery. The volumes of lubricating

oil provided to these parties in 2003 totaled approximately 107,600 litres.

SCRAP METAL

CF(L)Co., again in 2003, completed a successful year in its scrap metal recycling program. Approximately

81 tonnes of overhead ground wire from the 735 KV line and 91 tonnes of miscellaneous scrap metal from

outlying properties was recycled.

Hydro's Generation Division put a large focus on scrap metal recovery in 2003. Approximately eight tonnes

of condemned road culverts, structural steel, components of generating units and electrical panels that

had been accumulating for years was collected and sent for recycling. This compares to approximately 0.7

tonne recycled in 2002.

Our Transmission and Rural Operations Division, through auctions, sent approximately 54 tonnes of scrap

transformers and conductor to metal recyclers in 2003.

TREATED WOOD

Treated wood is essential for the reliability of wood pole transmission and distribution line systems

since treated wood has a longer service life than untreated wood. We recognize that treated wood must be

used and managed in a responsible manner. Whenever Hydro uses treated wood, specific guidelines are

followed to minimize the potential impact of preservatives on the surrounding environment. The potential

for wood preservative contamination during installation, maintenance and disposal are always

considered.

In 2003, Hydro implemented a new record keeping system in the Central Region to accurately track wood

poles. The system will be implemented in the other two regions in 2004. Approximately 80 percent of all

material removed from service is given to individuals or groups outside of Hydro for reuse, 15 percent

was taken from work sites before it could be transported to a storage area, and the remaining five percent

was held in storage for testing and recycling. Approximately 90 percent of this material was treated with

pentachlorophenol (Penta), eight percent was treated with copper chromated arsenate (CCA) and the remaining

two percent was treated with creosote. Disposal of treated wood at landfill sites is only considered if the

material is deemed unsalvageable. In 2003, approximately two tonnes of Penta treated wood was taken to

landfills for disposal.

Despite all reasonable efforts, Hydro continues to experience problems with the loss of salvageable

treated wood from work sites before it is moved to secured marshalling yards and/or depots. It is

speculated that this material is being taken by individuals who are taking advantage of the opportunity

to obtain building material that they believe is destined to be discarded as waste. Hydro will be

implementing measures to make the public aware that the use of this material for unauthorized purposes

can be hazardous.

In 2003, Hydro purchased 30 CCA, 15 Penta, and two untreated transmission poles, and 938 CCA, 64 Penta,

and 32 untreated distribution poles.

BOILER ASH

Boiler ash is produced at the Holyrood Thermal Generating Station as a result of the combustion

process. During 2003, approximately 600 tonnes of fuel ash was produced and disposed of at an on-site,

controlled solid waste landfill.

|